Driven by the global goal of carbon neutrality, the energy storage industry has ushered in opportunities for rapid development. By the end of 2023, the cumulative installed capacity of new energy storage projects that have been completed and put into operation nationwide has reached 31.39 million kilowatts/66.87 million kilowatt hours, with an average energy storage time of 2.1 hours; The newly added installed capacity in 2023 is about 22.6 million kilowatts/48.7 million kilowatt hours, an increase of over 260% compared to the end of 2022, and nearly 10 times the installed capacity at the end of the 13th Five Year Plan period. With the widespread application of renewable energy, energy storage technology has become the key to solving energy volatility and intermittency problems. However, energy storage technology also faces many challenges in its development process, among which safety issues are particularly prominent. Among them, hydrogen detection is an important issue in energy storage fire safety.

The key role of hydrogen sensors in the energy storage industry

In practical applications, the variation of lithium batteries in energy storage scenarios usually produces some gases, including hydrogen, toxic carbon monoxide, etc. Energy storage power stations use multiple sensors for comprehensive detection, and the application of hydrogen sensors in energy storage scenarios requires key functions such as real-time and accurate monitoring, temperature and pressure detection, etc.

1. Real time monitoring of hydrogen concentration

Real time monitoring of hydrogen concentration is one of the key functions of hydrogen sensors. The ProSense FC-H2-5000 hydrogen sensor can quickly respond to ppm level hydrogen detection and is widely applicable for detecting most hydrogen scenarios. In energy storage systems, changes in hydrogen concentration are directly related to the safety and stability of the system. The hydrogen sensor can detect abnormal concentration in a timely manner by continuously monitoring the hydrogen concentration. According to statistics, when the hydrogen sensor detects that the hydrogen concentration exceeds the safety threshold, it can issue a warning several minutes or even longer in advance, effectively preventing safety accidents such as hydrogen leaks and explosions.

2. Warning and alarm function

When the hydrogen concentration in the environment is abnormal, the detector equipped with a hydrogen sensor will immediately issue a warning or alarm signal, reminding relevant personnel to handle the abnormal situation in a timely manner.. In practical applications, once the sensor sends out a warning signal, relevant personnel can quickly take measures such as shutting down the system, conducting maintenance, etc., thereby nip the risk factors that may cause serious accidents in the bud.

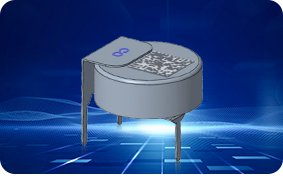

Advantages of ProSense FC-H2-5000 Hydrogen Sensor

The ProSense FC-H2-5000 long-life hydrogen sensor is based on the principle of micro fuel cells for detection. Its detection principle is as follows: when hydrogen gas is present in the environment, gas molecules quickly reach the core detection unit of the sensor through natural diffusion and concentration polarization, and undergo oxidation reaction at the positive electrode. Oxygen in the environment undergoes reduction reaction at the negative electrode of the sensor, forming a closed loop reaction. The generated current is proportional to the concentration of hydrogen gas in the environment. By detecting the magnitude of the generated current, the hydrogen gas content in the environment can be accurately quantified.

The FC-H2-5000 hydrogen sensor has the characteristics of high sensitivity and long lifespan. This sensor is a passive component with outstanding advantages such as zero power consumption, low noise, high detection accuracy, long service life, anti-interference, anti poisoning, and wide temperature range. Suitable for thermal runaway management of lithium batteries in the field of energy storage and firefighting.

Since its establishment, ProSense has provided over 10 million gas sensors in both domestic and international markets. The gas sensor product line produced by ProSense is very extensive, and its high stability and anti-interference characteristics make it suitable for various industries and harsh environments.

In the future, with the continuous advancement of technology, the performance of hydrogen sensors will continue to improve. Its detection accuracy will be higher, enabling more accurate monitoring of small changes in hydrogen concentration and providing more reliable data support for the safe operation of energy storage systems. The response speed will also be further accelerated, allowing for the detection of abnormal situations in a shorter period of time and buying valuable time for taking emergency measures. At the same time, the stability and reliability of the sensors will be further enhanced, improving the overall safety of the energy storage system.

Companies like ProSense are providing more comprehensive and reliable solutions for the industry. We believe that with the advancement of technology, hydrogen sensors will also play a more important role in emerging energy storage industries, such as hydrogen storage projects in large wind farms, hydrogen new energy vehicle industry, hydrogen fuel cells, etc. We can also wait and see.